|

|

| Home | Zinc Casting | Magnesium Casting | Automation | View our Videos | Various Alloys Parts | Latest Update | Location About Taiwan | Contact us |

|

|

| Home | Zinc Casting | Magnesium Casting | Automation | View our Videos | Various Alloys Parts | Latest Update | Location About Taiwan | Contact us |

Zinc Machines

|

|

| The Producer Company of Tainan, Taiwan is one of the leading manufacturers of hot chamber die casting machines and automation equipment in the international market since 1979. For over four decades, we have been dedicated to producing the highest quality and highest technology equipment to a variety of operations all over the world. |  |

| Producer’s headquarters in Tainan, Taiwan includes a state of the art manufacturing building with its own engineering, machining and assembly facilities as well as a complete testing and research and development capability. It is one of the only companies in Asia with this capability enabling it to maintain control over the quality of its products. Unlike other companies in the region that rely on subcontractors for much of their work, Producer owns their facilities and invite customers to visit our facility and encourage them to tour the inspection area, inventory, machine shop and assembly area. | |

|

We have sold and installed many new machines to a variety of customers ranging from smaller job shop die casters to large captive operations with dozens of machines. We can arrange visits and encourage our potential customers to ask for references to hear first hand from satisfied customers. In the highly competitive die casting business, it is extremely important to know your supplier and trust their service. We deliver what we promise and stand behind our products. Don't take our word for it; ask our growing customer list. |

Control System |

|

The control systems of all of our machines are designed to provide the highest level of reliability combined with the simplicity of a user-friendly touch screen interface to maximize production and minimize training requirements. We utilize a proven industrial grade programmable logic controller combined with an operator interface that allows control and setup of all operating parameters as well as providing diagnostics and memory for all machine functions. For pictures and further information on Control Systems, click here |

|

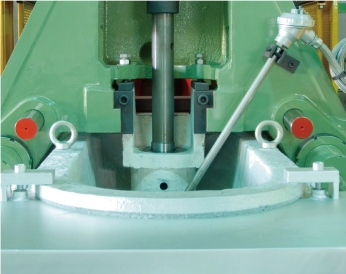

| Clamping System | |

| The heart of any die casting machine is the clamping system. Our machines have been designed and built to provide years of trouble free service. We have selected materials, components and designs, which have been proven in some of the harshest environments possible. Many manufacturers have built machines that appear similar to ours, but analyzing their entire structure, our machines come out on top. For pictures and further information on Clamping Systems, click here |

|

|

Every machine we build shares the same design including standard central motorized die height adjustment utilizing a strong bull gear; large diameter toggle pins and guide bars to insure years of safe operation. Larger models (P120 and above) also offer a central hydraulic platform to change shot positions. |

| The shot ends of our machines are constructed to withstand the severe heat and pressure present in all hot chamber die-casting shops. Heavy welded A frames straddle the furnace and allow flexibility for launder systems. The A frame, shot cylinder and front platen are water-cooled. Large diameter guide bars are furnished in addition to the nozzle adjustment, which is hydraulically operated and can be set to break away or remain fixed at the customer's option. Because of our six tie bar design, the toggle mechanism can be retracted away from the nozzle area for easy access and maintenance. |  |

|

Our new dipped style gooseneck design prevents freezeups and reduces porosity by immersing the gooseneck below the metal surface. Our shot ends are further enhanced with the addition of piston type accumulators for greater efficiency. |

| Our goosenecks are cast alloy steel with hardened solid bottom sleeves for maximum life. Massive shot cylinder, lines and porting and a dedicated shot end manifold with separate accumulator and controls enable the machines to produce high quality flash free castings. The hydraulic manifold has controls for single, two speed and in larger machines (P90-HP and above) intensification as well as a complete range of control of shot velocity. Many of the adjustments can be made from the operator interface and the others on valving on the manifold. Total adjustability of pressure, velocity and timing as well as memory retention of settings are standard on every machine | |

The hydraulic systems on our machines are perhaps the best feature we offer. A high-energy efficient motor and pump are located to maximize performance and minimize noise. We have recently engineered new high efficiency hydraulic circuits to use smaller pumps and still deliver higher speeds of operation while saving electricity. Separate manifolding for the clamping system, the shot system and on larger machines, the core pull and hydraulic ejection provide efficient delivery of the fluid to enable smooth, trouble free operation. By utilizing separate accumulators for developing closing speed and operating the shot system, we eliminate the need for larger, more energy consuming pumps and this allows lower operating pressure to provide stable performance with less maintenance required. All machines utilize our proven system that provides a large hydraulic fluid reservoir with baffling to isolate the suction and return sides of our system. A large capacity heat exchanger maintains proper operating temperature for the hydraulic fluid. All machines feature low pressure closing, automatic recycling, hydraulic multiple pulse ejection, hydraulic multiple sequence core pulls, motorized die height and two speed shot as standard. Speed and pressure can be individually adjusted on most of these features. Automation equipment and accessories for our machines were developed and are built in the same facility as our machines. Everything is designed to interface seamlessly with a minimum of setup required. We offer a dependable, proven vertical rotation extractor, a variety of reciprocating spray systems, a variety of conveyor systems utilizing both water quench and an air cooling tunnel and central hydraulic nozzle position changing. We can supply shot monitoring systems, chillers, vibratory finishing equipment, trim presses, weight sensing scales, special platen drilling and arrangements, special bases for custom installations and a variety of furnace and fuel options to suit any requirement. All models are supplied with a complete set of spare parts, tools, manuals, hand spray gun, die lifting boom (models up to P200), die clamps, a complete water manifold and drain system. Freight on all of our machines is included to the customer’s assigned seaport. We provide startup and training with every machine and we stand behind our products with a strong warranty and complete stock of spare parts and factory trained technicians to assist our customer base. |

|

| Safety Features | |

| All of our machines come equipped with a full complement of safety features including hydraulic and electric interlocks and guarding. Safety redundancy is provided in all of our circuit designs and critical backups are included. International safety standards including CE and ANSI as well as prevailing local codes are met or exceeded. Safety signs with pictorial symbols are affixed to all areas of the machine. | |

|

|

| PRODUCER CO., LTD. | Tel: +886-6-2663479 . 2661486 | |

| 15, Kai Fa 3rd Road, Pao An Village, Rende Dist., | Fax: +886-6-2660938 | |

| Tainan City, Taiwan | Website: www.producer-tw.com | |

| (Pao An Industry Park) | Email: rocky137@hotmail.com |